Safety

Pipelines are an extremely safe way to transport energy across the country. In fact, the Department of Transportation calls pipelines the safest mode of energy transportation. Accidents are rare, and INGAA’s members are committed to making them even rarer. Members have a goal of zero pipeline incidents. We are working every day toward that goal.

Regulators and industry experts alike, including the U.S. Department of Transportation, have agreed for decades that pipelines are the safest mode of energy transportation. Accidents are rare, and INGAA’s members are committed to making them even rarer. Our members work every day towards their shared goal of zero pipeline incidents.

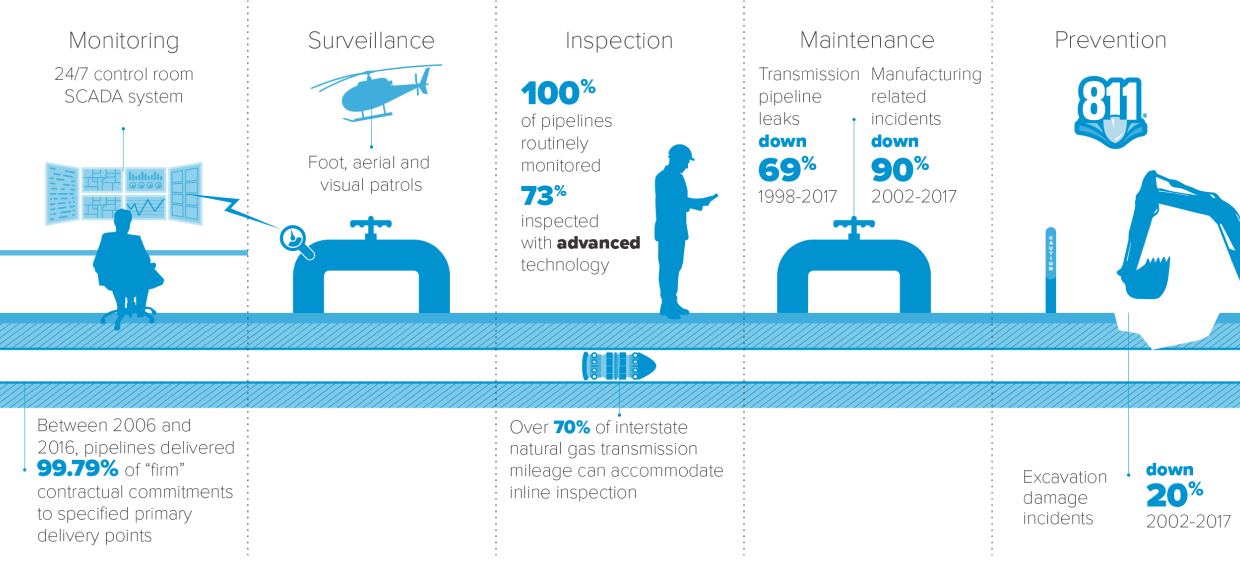

Pipeline companies consider safety every step of the way, from planning, to construction, to maintenance. Our members purchase top-quality materials, address any potential safety or security issues during the pipeline planning and citing process, and constantly check for quality and safety during the construction process. Once operational, pipeline companies work to prevent releases by evaluating, inspecting, and maintaining pipelines as part of a program called integrity management.

Integrity management programs generally focus on densely populated areas, but INGAA members have committed to expanding these practices to all areas of the pipelines where people might live, work, or recreate. Our members are also working on increasing the amount of pipeline mileage that can accommodate an inline inspection device, or a “smart pig.”

Read more about our IMCI Program

Our members are constantly making progress on our safety protocol. Pipeline incidents, including leaks, have fallen sharply since the implementation of the first integrity management programs in 1990.

Pipeline incidents, while rare, can still occur. Pipeline operators, with proper training and advanced control room technologies, are prepared to quickly stop the flow of gas in the unlikely event of a release. Operators also develop emergency response plans, deploy resources, and work frequently with local first responders to reduce the impacts of any incident. Members of the public that live near a pipeline are educated on what to do in the rare case of an emergency.

Pipeline operators work with the National Transportation Safety Board and the Pipeline and Hazardous Materials Safety Administration to determine incident causes, fix problems, and pay fines when appropriate.

Frequently Asked Questions

Pipeline leaks are rare, but being able to recognize and respond to a suspected leak or rupture is an important part of living and working safely around underground pipelines.

Signs of a natural gas pipeline RUPTURE:

Loud roaring or explosive sound; OR

Very large flames and loud roaring noise

Signs of a natural gas pipeline LEAK:

Rotten egg odor

Dead vegetation over or near the pipeline

Pigs are used to inspect pipelines. No, not the farm animals, but robotic devices called pigs because of the squealing sound they make when they travel through the pipelines. “Smart” pigs are used to evaluate the inside of the pipeline and ensure that they are safe. Pigs can ensure proper pipe structure, detect signs of corrosion or leaks and also can be used to clean the lines. Smart pigs are just one of the many ways that the pipeline industry ensures safety. Pipeline operators also conduct routine aerial and walking inspections of the pipeline and they monitor the pipeline’s pressure 24/7.

Yes. Pipelines are the safest, most reliable and efficient manner of transporting energy products.

The Department of Transportation, or DOT, oversees interstate natural gas pipelines, and they often note that pipelines are the safest form of energy transportation. Statistics gathered by the National Transportation Safety Board, a federal agency, indicate that pipelines make up less than one one-hundredth of one percent (.01%) of all transportation accidents in the United States. There are approximately 300,000 miles of natural gas transmission pipelines throughout the United States that deliver safe, reliable natural gas to American families and businesses.

Pipelines exist almost everywhere throughout the United States -generally buried underground – transporting the energy that you depend on every day to heat your home, generate electricity, cook your food and so much more. Pipelines are a vital and efficient part of the United States’ energy infrastructure.

Yes. Any land disturbance for pipeline construction is temporary. Pipeline construction crews work to restore the land to its previous state. With the exception of pipeline safety markers located at each crossing of a public road and railroad and anywhere else necessary to identify the location of a pipeline, underground gas pipelines are largely invisible as they transport energy.

After a line is built, you can carry on normal farming operations, including crop growing and grazing. And because pipelines have at least 36 inches of soil cover, there should be no obstacles to normal irrigation or cultivation. You cannot plant trees on pipeline rights-of-way, nor can you build homes or business facilities. These restrictions are in place for safety and for pipeline maintenance purposes. They also may affect the value of the land, which will be reflected in the compensation that the landowner receives from the pipeline company.

After construction of the pipeline, the company will periodically inspect the site to ensure it is being properly maintained. Inspections are done from airplanes as well as on foot. It is the responsibility of the pipeline company to maintain the site, through such activities as mowing fields and clearing trees. These maintenance activities help the company properly inspect the site.

Think of a natural gas pipeline as an energy highway. American pipelines transport natural gas from nearly 275,000 gas wells in various production areas of the country over hundreds or thousands of miles to customers in cities, towns and industrial facilities.

The gas is compressed when it comes out of the wells, and this compression helps it move at about 15 miles per hour through the pipes. Though the friction of the gas against the pipes slows it down at some points along the way, the pipelines operate compressor stations at points about 75 miles apart along the route to compress the natural gas and then push it along. The natural gas in a pipeline is roughly the same temperature as the earth around the pipeline, though the periodic compression can increase the temperature for a short distance.

The gas moves relatively quietly on its journey through the pipeline system. The only noise comes at the compressor stations, whose motors generate the equivalent noise of a plane engine. To minimize noise, compressor stations, which are about the size of a barn, are insulated and operate under federal regulations and specifications. Natural gas is delivered to local gas distribution companies (LDCs), which in turn distribute the gas to homes, businesses and factories. Pipelines also deliver gas to end-users, such as electric generators.

The following are a few of the agencies that regulate natural gas pipelines:

The Federal Energy Regulatory Commission (FERC) regulates such things as natural gas transportation rates, pipeline capacity, pipeline siting and natural gas quality requirements.

The U.S. Department of Transportation (DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA) and their state and local agents provide regulation for the safe transportation of natural gas through pipelines.

The U.S. Environmental Protection Agency (EPA), the Fish and Wildlife Service and state environmental protection agencies provide regulations for protection of the environment and cultural resources during the construction and operation of pipeline facilities.

The U.S. Occupational Safety and Health Administration (OSHA) provides regulation for the safe working place for personnel.